Products > drillingtools

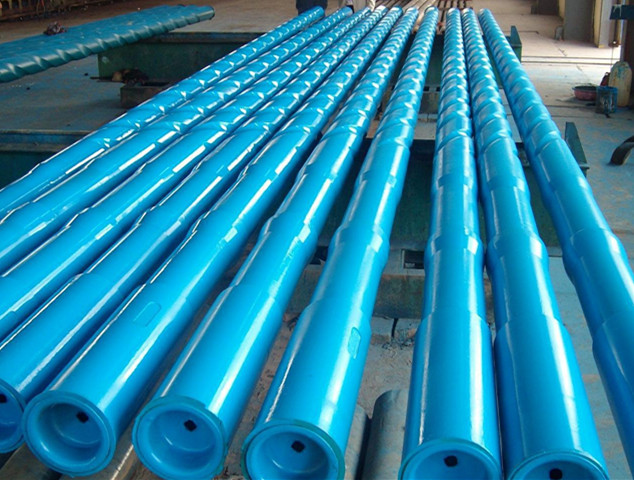

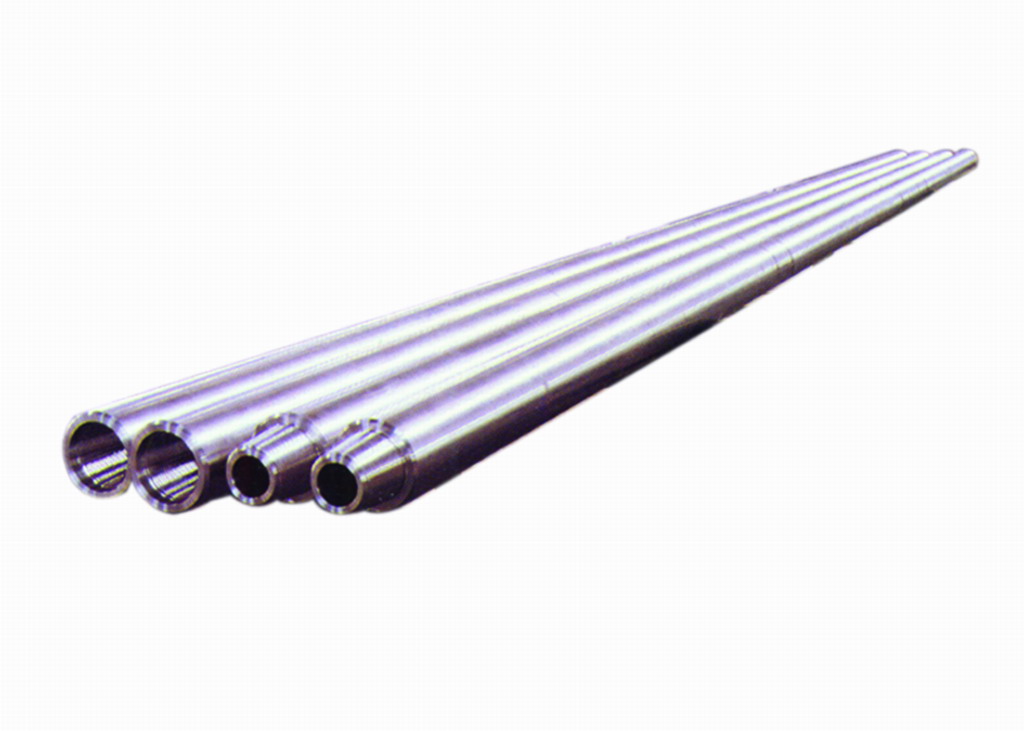

Kingwell supplies slick drill collars, spiral drill collars and non-magnetic drill collars etc. The size of drill collar is from 3-1/8 to 11 inches.

Drill collars are manufactured strictly according to API Spec7-1 standard.

Material: 4145H, 4145H Mod, Non Magnetic

Type: Slick Drill Collar, Spiral Drill Collar

Size: 3 1/8" - 14"

Hardbanding: ANRCO 100 XT, 200XT, 300XT.

KINGWELL is young team who is dedicated to provide global customer base with quick turnaround solutions extends across the entire drilling solutions. Kingwell team can provide bespoke. fit for purpose solutions, and rapidly convert concept to completion.

l Konwledge, technical innovation and teamwork are at the center of who we are. we have focused on leveraging these assets to deliver solutions that improve customer performance.

l Working with an experienced and dynamic team like us, you'll never be disappointed. Pls contact us to achieve your plan.

Drill collars are manufactured strictly according to API Spec7-1 standard; The size of drill collar is from 3-1/8 to 11 inches.

Material: 4145H, 4145H Mod, Non Magnetic

Type: Slick Drill Collar, Spiral Drill Collar

Size: 3 1/8" - 11"

Hardbanding: ANRCO 100 XT, 200XT, 300XT.

• Slick

• Flex

• Spiral

• Special

• Slick Non-Mag Drill Collar

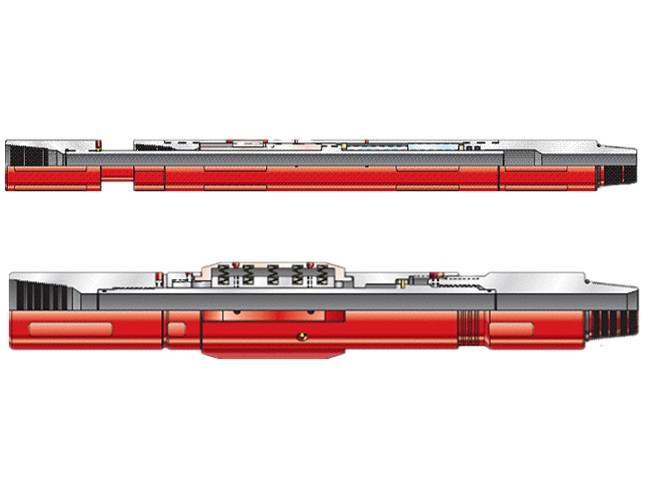

Kingwell Slick Non-Mag Drill Collar provides the required weight on bit, and will not interfere with the directional drilling ability.• Spiral Non-Mag Drill Collar

Kingwell Spiral Non-Mag Drill Collar is designed to allow greater flow area for drilling fluids, while providing the benefits of non-mag steel for complex drilling programs.• Flex Non-Mag Drill Collar

Kingwell Flex Non-Mag Drill Collar is thinner and more flexible than standard drill collar. Their ability to make short radius turns, bend for high build angles, and pass through severe doglegs makes them ideal for use in directional and horizontal applications. Manufactured with non-mag steel, this drill collar is well suited for housing MWD equipment.When ordering please specify:

• Drill collar OD and ID;

• Material;

• Overall length;

• Connections required (size and type);

• Special features desired, for example;

• Slick、Spiral、Flex、Special;

• Stress Relief Features;

• Hardbanding;

The Non-mag Drill Collar has an important role in the bottom hole assembly.

Non-mag drill collars are used to provide magnetic spacing, protecting the downhole directional sensors from magnetic interference. Kingwell offers non- mag drill collars that from a specific alloy of non-magnetic elements, manufactured as API standards.

Non-mag Drill Collar

The following special processes are uniformly compressed surface layers:• Hammer Peening

• Roller Burnishing

• Shot Peening

The pitting and stress corrosion resistance of non-magnetic drill collars is improved by increasing the content of Chromium, Molybdenum, Nitrogen and other alloying elements.

All Kingwell non-magnetic materials generally exhibit excellent stress corrosion resistance

Testing of drill collars during production:

• Impact Test

• Tensile Test

• Hardness Test

• Oxalic Acid Test

• Metallographic

• Ultrasonic Test

Probe Test

KINGWELL Drill Collar Technical Data:

| OD | ID | L(mm) | DF(mm) | Bending Strength ratio |

Drill Collar Nominal size |

||

| mm | in | mm | in | ||||

| 79.4 | 3-1/8 | 31.8 | 1-1/4 | 9,150 | 76.2 | 2.57:1 | NC23-31 |

| 88.9 | 3-1/2 | 38.1 | 1-1/2 | 9,150 | 82.9 | 2.42:1 | NC26-35(2-3/8IF) |

| 104.8 | 4-1/8 | 50.8 | 2 | 9,150 | 100.4 | 2.43:1 | NC31-41(2-7/8IF) |

| 120.7 | 4-3/4 | 50.8 | 2 | 9,150 | 114.7 | 2.58:1 | NC35-47 |

| 127 | 5 | 57.2 | 2-1/4 | 9,150 | 121 | 2.38:1 | NC38-50(3-1/2IF) |

| 152.4 | 6 | 57.2 | 2-1/4 | 9,150/9,450 | 144.5 | 2.49:1 | NC44-60 |

| 152.4 | 6 | 71.4 | 2-13/16 | 9,150/9450 | 144.5 | 2.84:1 | NC44-60 |

| 158.8 | 6-1/4 | 57.2 | 2-1/4 | 9,150/9,450 | 149.2 | 2.91:1 | NC44-62 |

| 158.8 | 6-1/4 | 71.4 | 2-13/16 | 9,150/9,450 | 150 | 2.63:1 | NC46-62(4IF) |

| 165.1 | 6-1/2 | 57.2 | 2-1/4 | 9,150/9,450 | 154.8 | 2.76:1 | NC46-65(4IF) |

| 165.1 | 6-1/2 | 71.4 | 2-13/16 | 9,150/9,450 | 154.8 | 3.05:1 | NC46-65(4IF) |

| 171.4 | 6-3/4 | 57.2 | 2-1/4 | 9,150/9,450 | 159.5 | 3.18:1 | NC46-67(4IF) |

| 171.4 | 6-3/4 | 71.4 | 2-13/16 | 9,150/9,450 | 159.5 | 2.37:1 | NC50-67(4-1/2IF) |

| 177.8 | 7 | 57.2 | 2-1/4 | 9,150/9,450 | 164.7 | 2.54:1 | NC50-70(4-1/2IF) |

| 177.8 | 7 | 71.4 | 2-13/16 | 9,150/9,450 | 164.7 | 2.73:1 | NC50-70(4-1/2IF) |

| 184.2 | 7-1/4 | 71.4 | 2-13/16 | 9,150/9,450 | 169.5 | 3.12:1 | NC50-72(4-1/2IF) |

| 196.8 | 7-3/4 | 71.4 | 2-13/16 | 9,150/9,450 | 185.3 | 2.70:1 | NC56-77 |

| 203.2 | 8 | 71.4 | 2-13/16 | 9,150/9,450 | 190.1 | 3.02:1 | NC56-80 |

| 209.6 | 8-1/4 | 71.4 | 2-13/16 | 9,150/9,450 | 195.7 | 2.93:1 | 6-5/8REG |

| 228.6 | 9 | 71.4 | 2-13/16 | 9,150/9,450 | 212.7 | 3.17:1 | NC61-90 |

| 241.3 | 9-1/2 | 76.2 | 3 | 9,150/9,450 | 223.8 | 2.81:1 | 7-5/8REG |

| 247.6 | 9-3/4 | 76.2 | 3 | 9,150/9,450 | 232.6 | 2.57:1 | NC70-97 |

| 254 | 10 | 76.2 | 3 | 9,150/9,450 | 237.3 | 2.81:1 | NC70-100 |

| 279.4 | 11 | 76.2 | 3 | 9,150/9,450 | 266.7 | 2.84:1 | 8-5/8 REG |

• Pre-sale: Communicate with customer about drill collar information and select quality raw materials.

• In-sale: Strictly control each production link according to API standards and share different drill collar production schedule with our valued customers.

• After-sale services: Provide a drill collar quality certificate(Chemistries, Mechanical properties, Product size, Ultrasonic inspection...) and resolve customer problems during use.

Products

+Drilling Equipment

- Drill Collar

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker

+APR Drill Stem Testing Tools

- Subsurface Control Valve (SSC) Storm Vavl

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Champ v Packer

- Storm Valve

- Tester Valve